- Home

- Sustainability

- Clean Manufacturing

Clean Manufacturing

Process-level environmental control

Manufacturing—especially denim manufacturing—has environmental impacts. We focus on measurable practices to manage water, energy, chemicals, and waste across our operations.

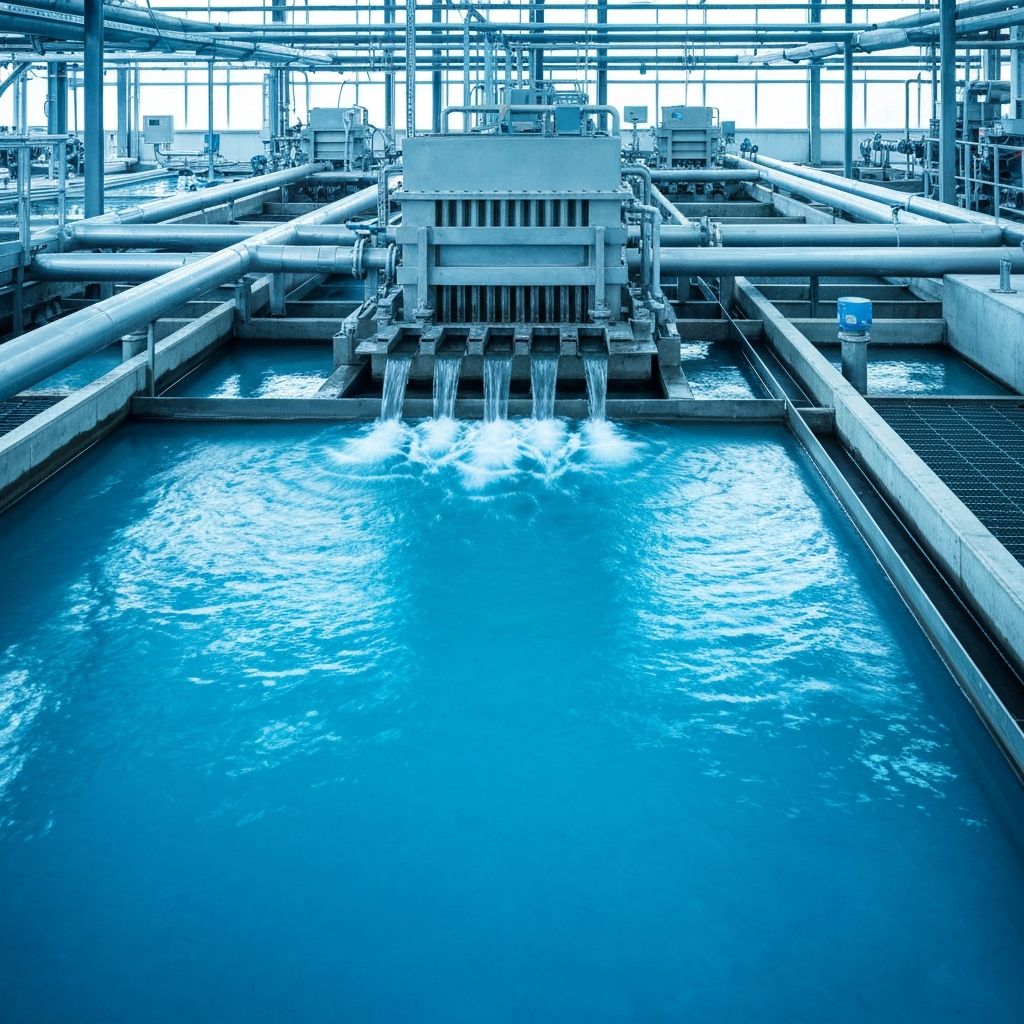

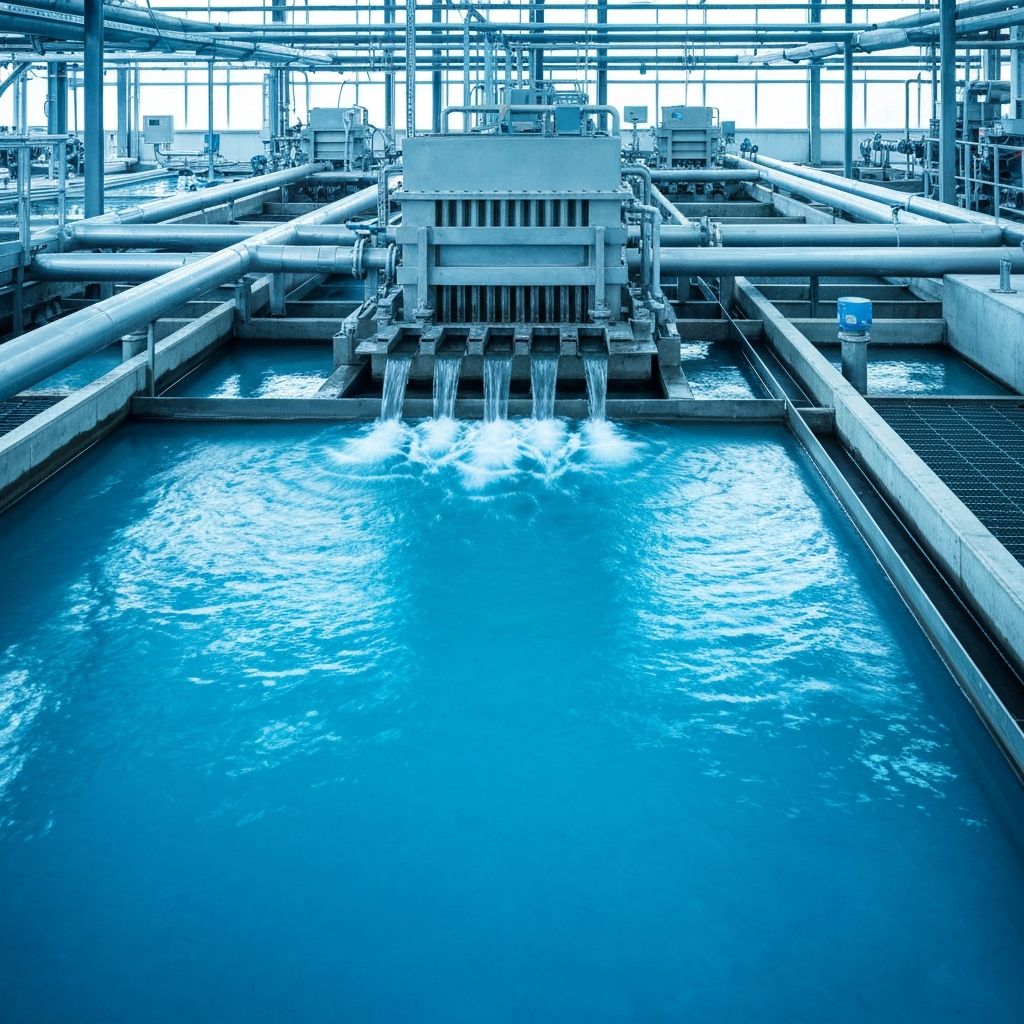

Water Management

Water is denim manufacturing's most significant environmental input. We manage it carefully.

- Water recycling systems in washing operations

- Low-liquor ratio dyeing processes

- Ozone and laser finishing to reduce wet processes

- Water quality monitoring and treatment

Energy Awareness

Energy consumption across manufacturing operations with ongoing efficiency improvements.

- LED lighting throughout facilities

- Equipment efficiency monitoring

- Natural ventilation where possible

- Process optimization to reduce energy waste

Chemical Management

Responsible chemical use with proper handling, storage, and disposal protocols.

- ZDHC MRSL compliance pathway

- Restricted substance testing

- Chemical inventory management

- Proper storage and handling procedures

Waste Reduction

Minimizing waste generation and maximizing material utilization.

- Marker optimization for fabric utilization

- Cutting waste recycling programs

- Proper waste segregation

- Packaging waste reduction

Water Recycling Systems

Reducing water consumption in wash operations

Laser Finishing

Low-impact processes

Continuous improvement

Clean manufacturing is not a destination—it's an ongoing commitment. We continuously evaluate our processes, invest in better equipment, and adopt improved practices as they become available and economically viable.

We avoid making absolute claims because manufacturing realities are complex. What we can commit to is transparency about our current practices and genuine effort toward improvement.

Questions about our manufacturing practices?

We welcome specific questions about our environmental management systems and practices.

Clean Manufacturing - FAQs

Common questions about our environmental management practices