OEM Manufacturing

Your designs, our precision execution

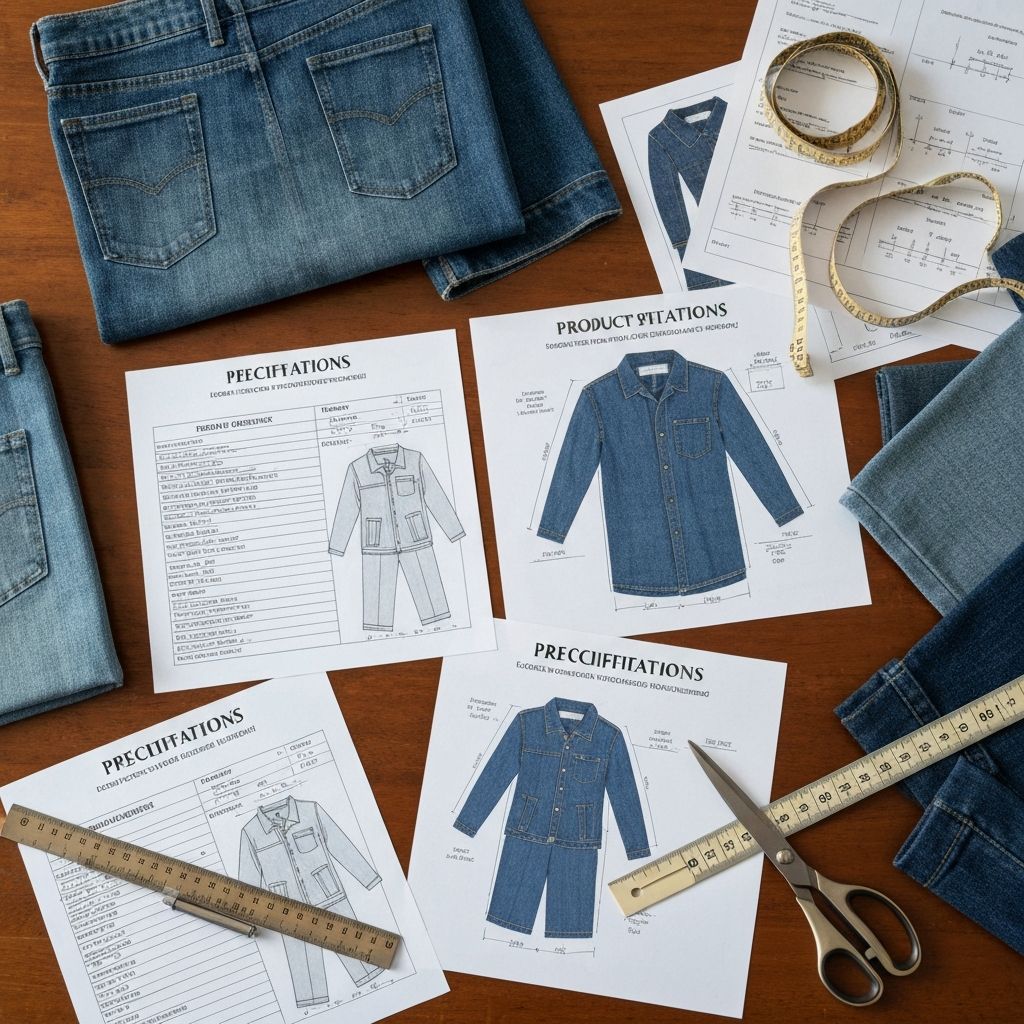

You have the designs. You have the specifications. What you need is a manufacturing partner who can execute with precision, maintain consistency across orders, and scale with your growth.

What OEM manufacturing means with us

OEM (Original Equipment Manufacturer) manufacturing means we produce garments according to your exact specifications. You provide the designs, tech packs, and quality standards—we handle the production with precision and accountability.

This model is ideal for brands and retailers who have established design capabilities and need a reliable production partner who can execute consistently at scale.

Ideal for:

- Established brands with in-house design teams

- Retail chains with private label programs

- Buying houses managing multiple brand accounts

- Brands transitioning from other suppliers

What you gain with our OEM services

Specification Precision

Your tech packs are followed exactly. Any clarifications are communicated before production begins.

Process Control

Every stage from cutting to finishing follows documented procedures for repeatable quality.

Scalable Capacity

Start with pilot orders and scale to full programs as your business grows.

Risk Management

Transparent communication, documented processes, and compliance-ready operations.

OEM production process

A structured process that ensures your specifications are followed precisely from initial review through final delivery.

Tech Pack Review

We analyze your technical specifications, identify any clarifications needed, and confirm feasibility.

Costing & Planning

Detailed cost breakdown and production timeline based on your requirements and quantities.

Sample Development

Proto samples for fit and construction approval before moving to production.

Pre-Production

Final samples, fabric and trim sourcing, production preparation and scheduling.

Bulk Production

Full production with inline quality checks and regular status updates.

Quality & Delivery

Final inspection, packing per specifications, and coordinated shipment.

Quality assurance at every step

Quality in OEM manufacturing is not just about final inspection—it is built into every stage of production. From incoming fabric inspection to in-line checks to final audit, we maintain your standards throughout.

- Incoming material inspection and testing

- In-line quality checks during production

- End-line inspection before packing

- AQL-based final audit before shipment

Have designs ready for production?

Share your tech pack and requirements. We'll review feasibility and provide a detailed proposal.

OEM Manufacturing - FAQs

Common questions about our OEM production services