- Home

- Innovation

- Wash Innovation Studio

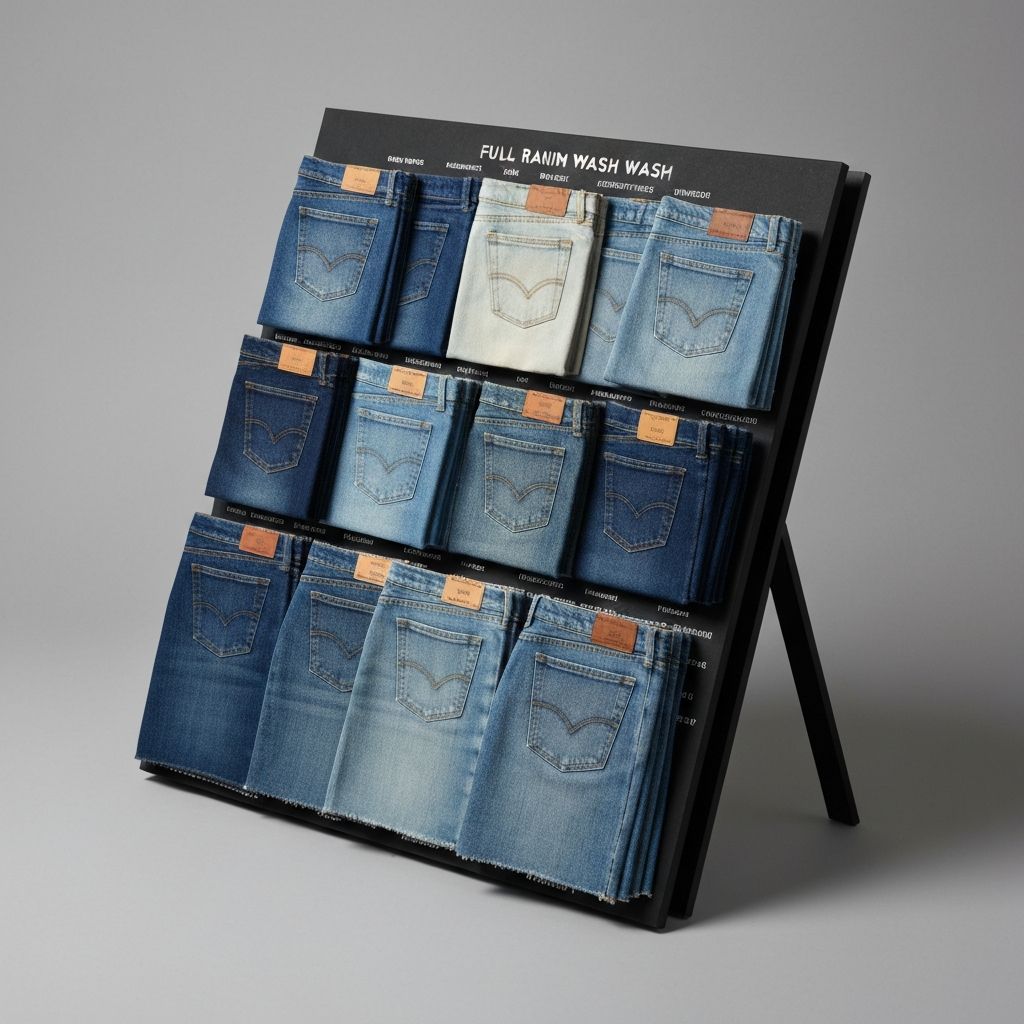

Wash Innovation Studio

Creativity meets sustainability

Denim washing is where fabric becomes product character. Our wash studio combines traditional craftsmanship with modern technology to create effects that are both aesthetically compelling and more environmentally responsible.

Wash capabilities

Low-Impact Techniques

Wash processes designed to minimize environmental impact while achieving desired aesthetics.

- Ozone treatments for color reduction

- Nebulization for reduced water usage

- Enzyme washes as chemical alternatives

- E-flow technology

Laser Applications

Precision laser technology for effects that would traditionally require heavy chemical or manual processes.

- Whisker and chevron patterns

- Distressing and abrasion effects

- Graphic applications

- 3D effects

Traditional Craft

Hand-finishing techniques executed by skilled artisans for authentic vintage effects.

- Hand sanding and scraping

- Resin applications

- Tinting and overdyeing

- Repair and destroy effects

Wash development expertise

Every wash starts with understanding your vision. We develop washes through iterative sampling—refining color, contrast, and effects until the wash meets your approval. Once approved, we document the recipe for consistent bulk production.

For sustainable wash development, we can guide you toward techniques that achieve your aesthetic goals with reduced environmental impact.

Sustainability through technology

Modern wash technology allows us to achieve the same or better effects with reduced environmental impact.

Water

Ozone and laser processes significantly reduce water consumption compared to traditional wet finishing.

Chemicals

Technology-assisted processes reduce reliance on harsh chemicals like potassium permanganate.

Energy

More efficient processes and modern equipment reduce overall energy consumption.

Consistency

Technology-assisted processes deliver more consistent results, reducing rework and waste.

Have a wash vision to develop?

Share your inspiration and let's discuss how to bring it to life sustainably.

Wash Innovation Studio - FAQs

Common questions about our wash development capabilities